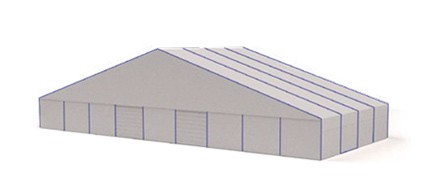

CONSTRUCTION:

Main construction molding 460 x 170mm, pressed from 6061 T6 or 6082 T6 aluminum alloy, for event purposes it is possible to make anodized profiles

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material with a weight of 670 – 900 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

CONSTRUCTION:

Main construction molding 304 x 136mm or 314 x 122mm, pressed from 6061 T6 or 6082 T6 aluminum alloy, for event purposes it is possible to make anodized profiles

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material with a weight of 670 – 900 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

CONSTRUCTION:

Main construction molding 253 x 131mm, pressed from 6061 T6 aluminum alloy, for event purposes it is possible to make anodized profiles

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material with a weight of 670 – 900 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-35 profile

Sandwich panel filled with polyurethane foam, 60mm

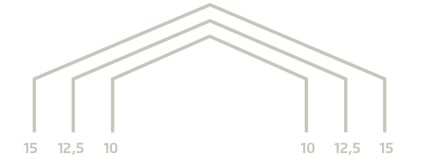

CONSTRUCTION:

Main construction molding 150mm x 100mm, pressed from 6061 T6 aluminum alloy

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material with a weight of 670 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-35 profile

Sandwich panel filled with polyurethane foam, 60mm

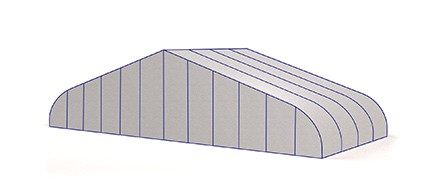

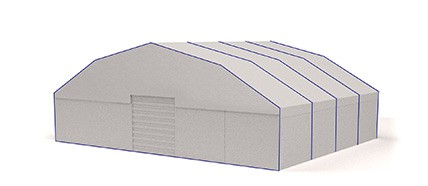

CONSTRUCTION:

The main profile of the structure complies with GAMMA 1, GAMMA 2 or DELTA profiles, pressed from 6061 T6 aluminum alloy

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material with a weight of 670 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-35 profile

Sandwich panel filled with polyurethane foam, 60mm

CONSTRUCTION:

Main construction molding 460 x 170mm, pressed from 6061 T6 or 6082 T6 aluminum alloy, for event purposes it is possible to make anodized profiles

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material with a weight of 670 – 900 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-35 profile

Sandwich panel filled with polyurethane foam, 60mm

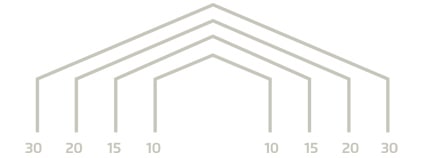

CONSTRUCTION:

Main construction molding 314 x 122mm, pressed from 6061 T6 or 6082 T6 aluminum alloy, for event purposes it is possible to make anodized profiles

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material with a weight of 670 – 900 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-35 profile

Sandwich panel filled with polyurethane foam, 60mm

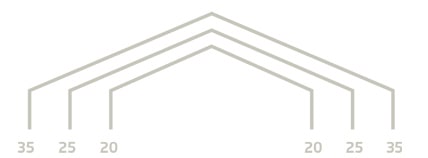

CONSTRUCTION:

Main construction molding 307mm x 114mm, pressed from 6061 T6 aluminum alloy, for event purposes it is possible to make anodized profiles

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard

ROOF COVER:

Tarpaulin PCV material with a weight of 670 – 900 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-35 profile

Sandwich panel filled with polyurethane foam, 60mm

CONSTRUCTION:

Main construction molding 170mm x 88mm or 214 x 100mm, pressed from 6061 T6 aluminum alloy

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material with a weight of 670 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-35 profile

Sandwich panel filled with polyurethane foam, 60mm

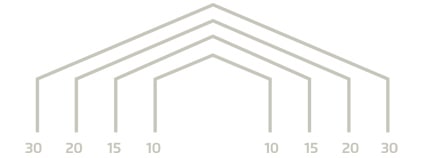

CONSTRUCTION:

Main construction molding 460 x 170mm, pressed from 6061 T6 or 6082 T6 aluminum alloy, for event purposes it is possible to make anodized profiles

LINKERS:

Steel linkers mare from S355 alloy sections welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material with a weight of 670 – 900 g/m2 non-combustible in accordance with the standard EN 13501-1

SIDE WALL CASTING:

PCV material

TEMPORARY WAREHOUSE - PORTFOLIO

1600 TENT HALLS ANNUALLY

Temporary warehouses. Quality, stability of construction, safety

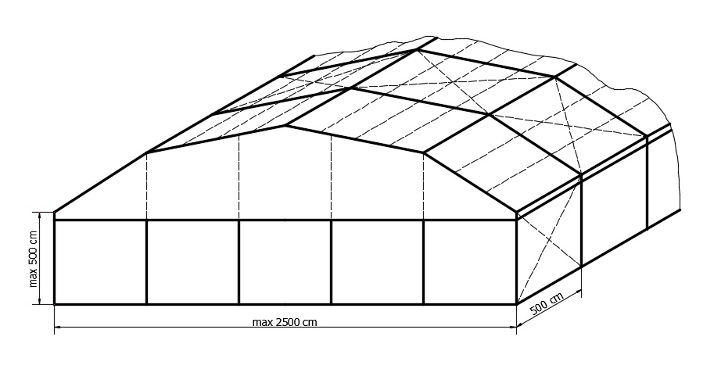

Attention to details, proven design solutions, guaranteed durability and stability of construction of the tent hall – without any support and internal lines – allows to use the full volume of the hall.

Tent hall – warehouse for a yacht shipyard.

Pumped roof increases the thermal isolation of the hall and facilitates the removal of snow.

A pump is a necessary equipment for tent halls with a pumped roof.

Pumped roof increases the thermal isolation of the hall and facilitates the removal of snow.

Rapid installation without ladders: 20 minutes – one day.

Hinge support mechanism allows for the installation of the roof at low heights. Standard tent halls and pavilions are installed in 20 minutes, storage tents with an area of 1000m2 in a single day.

Durable aluminum-based construction – no rust!

Tent halls made from anodized aluminum guarantee a lightweight construction, excellent durability and resistance to atmospheric factors.

Easy expansion of the hall – innovative segments.

The modular construction allows to combine the tent halls into any configurations, including floors, and easily add new segments.

FUNCTIONALITY – VERSATILITY OF USE

STORAGE HALLS – LOGISTIC CENTRES

INDUSTRIAL HALLS

PAINTSHOPS

CARWASH

WASTE SORTING PLANTS

PIGPENS – COWSHEDS – HEN HOUSES – CHAMPIGNON STORING HALLS – FRUIT SORTING PLANTS

STABLES – HORSE RIDING FACILITIES

SPORT HALLS – TENNIS COURTS – ICE RINKS

building, industry, logistics, automotives, trade, agriculture

WHY TENT HALLS?

- COST-EFFECTIVE ALTERNATIVE TO HEAVY BUILDINGS

- MOBILITY, FAST INSTALLATION AND REMOVAL (1 TO 2 DAYS)

- DURABILITY – MINIMUM 10 years

- RESISTANCE TO EXTREME WEATHER CONDITIONS – WIND, SNOW, HAIL, RAIN

- TAILORED SOLUTIONS (INSULATED WALL PANELS, ENTRANCE GATE, WINDOWS AND DOORS, PUMPED ROOF)

1600+

TENT HALLS PER ANNUM

WE INSTALL

1600+

TENT HALLS PER ANNUM

WE WORK GLOBALLY

The quality of our tent halls is appreciated by clients all over the world.

SPITSBERGEN, OMAN, NORWAY, SAUDI ARABIA, RUSSIA, GREECE, FRANCE, GERMANY, GREAT BRITAN, SPAIN, HOLLAND, ITALY

Our tent halls will really endure even the most extreme weather conditions!

Aluminium construction – snow load of up to 150 – 300 kg/m²!